Final Installation / Light Testing

Detail Elevation: Mechanical Connections

RESPONSIBILITIES

I co-managed the project and using CAD and digital fabrication tools, oversaw its fabrication in our SF studio and on site in Denver.

Colliding energy waves during design phase simulations

Fabrication in SF studio

WAVEFORM. Built for Lockheed Martin's Aerospace Center at the University of Denver, this LED integrated facade mimics the visual affect supersonic speed.

Materials: Steel, Wood, LEDs, Acrylic, Aluminum

ELEVATION VIEW: SCALE

AXON VIEW

LIGHTSTREAM. Built for New York MTA’s Brooklyn Metro Station is a generative artwork that responds to passengers entering and exiting the trains. The ebb and flow of traffic triggers cascading patterns of light to ripple up and down the platform.

Scheduled for installation early 2019.

Materials: Steel, Wood, LEDs, Acrylic, Aluminum

Rendering of Train Platform. Octane Render

Elevation Section View: One of the Platform Panels Mounted on the Wall

CAD Model of single and double-wide panels

Responsibilities

I co-project managed, designed, and fabricated all physical aspects of this project. I took the conceptual model of our principle architects and went through numerous prototype phases to develop a platform wide installation of 16 modules of varying size and affect. Design objective: to create an elegant aesthetic that enhances the performance of the lights while making it weather resistant, tamper proof, and easy to maintain.

First prototype with welded stainless steel frame and integrated LEDs

Plan view detail of custom bolt/locking mechanism that holds the hinging door closed.

POWER-LIGHT-SPEAKER easily allows you to charge your phone, your computer, and other devices while setting the mood with an RGB voice activated light and integrated speaker system. It features a “wiggle-proof” cleat that holds perfectly to a wall or table to alleviate the struggle of plugging and unplugging with two hands.

Born out of frustration with the basic home and office power strips, this concept project is a labor of love that turns a cumbersome utility that clutters a room into a cross functional pleasure to have around.

Process sketch

Design Objectives:

MAKE POWER STRIPS EASY TO MOUNT. Wireless power is the future but until then, I'm tired of power strips that are near impossible to fix to a wall by aligning two screws that they don't come with and barely hold the it to the wall making it necessary to use to hands to unplug something.

STOP RUINING THE FUN SHUI OF A ROOM. Make them nice on the eyes. Beautiful finishes, subtle details, creative colors, making them nice would go a long way. I love my LifX Alexa voice activated night lights. I love my voice activated speakers. They both just sit off in the corner right night to my power strips. Why not combine these options int a compact unit that is an asset to a room not an eyesore?

WiFi ROUTERS SUCK. LETS FIX THAT WITH INTEGRATION. The oh-so ugly WiFi router sits on the same cold rung in my book ugly stuff in a home or office. By connecting this device online and activating it via your internet provider it function as a WiFi tranciever.

Inspired by California's native Anemone plant. Know as "Daughter of the Wind" in Greek, ANEMONE is a permanent public artwork installed in Albany CA.

Materials: Steel and Corian

Responsibilities

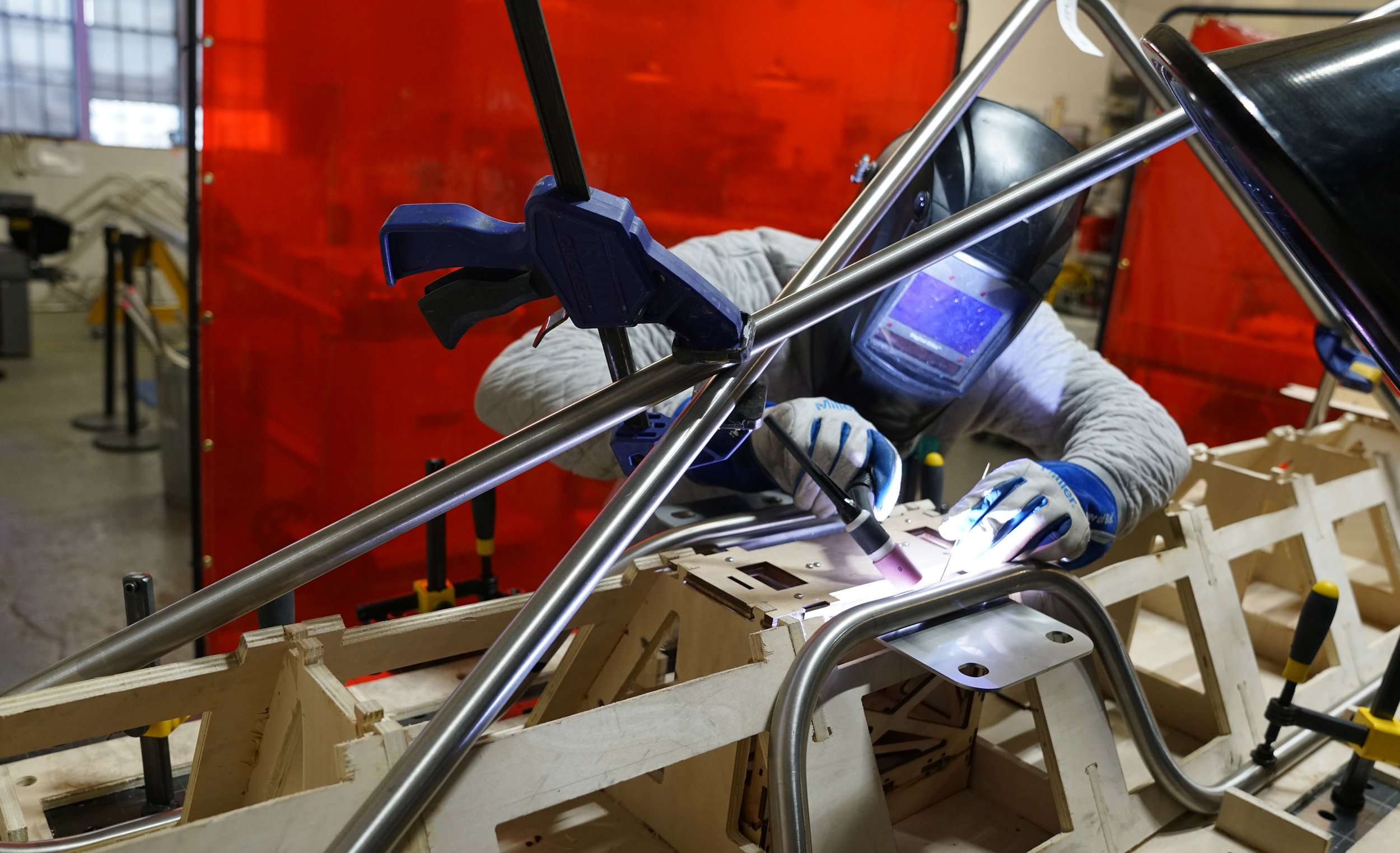

As my first project at Future Cities Lab, my role was to assist our concept designers adapt the 3D CAD models into fabrication diagrams that showed bending schedules for an hydraulic tube bender, tube notcher, and do CAM layouts for the G-code to mill Corian panels on a 3-axis CNC router. As a certified welder in California I also welded much of the final structure before shipping it off for galvanization and powder coating. I organized the final installation details and worked with riggers and crane operators on site to physically install the work on site in Albany.

Materials & Techniques

THE SUPPORT JIG FOR WELDING

The design of ANEMONE is a beautiful series of complex intersecting points that expand outward into their individual pedal clusters as the whole compositions slopes gently downwards. This synchronistic movement was created parametrically in Grasshopper 3D and baked into Rhino to be developed into CAM settings for fabrication. Each bend angle and waterjet cut component was was digitally tested through simulations before being prototyped and confirmed as successful. Once the geometries were confirmed, we built an extensive wooden jig to hold the steel at precise angles whiles being welded in place. We worked with engineers to sign off on the structural integrity of our componetns before having them waterjet cut by a 3rd party fabricators. The curved steel bars were bent using a hydraulic bender in our shop space in San Francisco before being welded together, powder coated, and mechanically fastened. The column bases were welded and hot-dip galvanized, before be installed on site. Once the steel structures were complete, we milled out the white and aqua colored corian panels and installed them in the steel structure before using a crane to lift them all in place.

SECOND PHASE OF 3D MODELS

FINAL INSTALLATION OF ANEMONE

Design Objective:

CREATE A DYNAMIC SHADE CANOPY THAT CHANGES WITH THE TIME OF DAY. The concept of light and shadow as a building block for the life of the Anemone plant was foundational and infiltrated the direction of the design from the start. Jason our founder would discuss how the structures themselves should be beautiful yet also just be a tool for the sun to pattern the ground. Parametrically spacing the holes cut in the Corian and creating upward and downward folds throughout the canopy allowed

WELDING ONE OF THE STRUCTURE

CAN OUR URBAN ENVIRONMENTS BECOME SENTIENT PARTICIPANTS IN OUR DAILY LIVES? CAN THESE IMMERSIVE SPACES ACTIVATE OTHERWISE NEGLECTED VOIDS?

Responsibilities

Lighting test at our design studio in San Francisco

Over a football field in length, this project presented unique design and fabrication challenges that our team overcame to complete this installation for the city of Washington D.C. I co-project managed the project's completion with our head designer Jeff, him doing schematic designs, me overseeing the mechanical details, materials, finishes, and fabrication schedules. Similar to our other projects, I executed a 3-step process to solve design concerns during the fabrication process. First getting started with quick and dirty prototypes until we had identified our known unknowns. We then extensively built out each section until the project coalesced and aligned in physical space. Once we were confident in our revised computer models after prototyping and the material details had been confirmed, we used CNC tube benders, Waterjet cutters, other digital fabrication tools and 4 months of welding to bring this project to life. Be built everything from scratch in our shop and design studio down to soldering the electronic wires and creating outdoor rated IP cable connectors.

Design Objectives:

CAN THESE IMMERSIVE SPACES ACTIVATE OTHERWISE NEGLECTED VOIDS? LIGHTWEAVE is positioned along a walkway beneath a train overpass near central station in Washington D.C. The site of an underpass can be considered a neglected space in cities, with this project we wanted to bring that space to life with the concept of a light guiding the way.

CAN OUR URBAN ENVIRONMENTS BECOME SENTIENT PARTICIPANTS IN OUR DAILY LIVES? From the outset making LIGHTWEAVE interactive was central to the design objectives. Integrated with sensors that detect sound and movement that alter the pace and color of light, the progressing light acts as a companion to pedestrians along their way.

Render of site for initial design proposal

Preliminary rendering during the proposal phase

Plan view of two two portions